By Warren Duffie Jr., Office of Naval Research

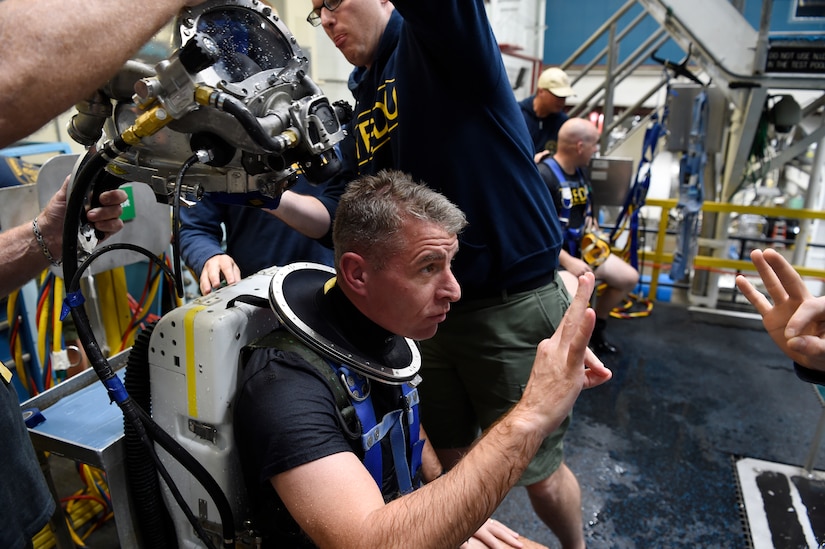

ARLINGTON, Va. -- The Navy diver hoisted a 60-pound

life-support regulator onto his back, then donned a 30-pound metal helmet.

Fellow divers connected his diving suit to an “umbilical”

hose pumping in breathing gas and establishing communications with the surface.

After receiving approval to enter the water, the diver descended into a large

test pool at Naval Surface Warfare Center Panama City Division, Florida, home

to the Navy Experimental Diving Unit.

New System

The diver’s mission: demonstrate the effectiveness of the

MK29 Mixed Gas Rebreather -- a prototype system that’s the first of its kind

within the Navy diving community, developed by Naval Surface Warfare Center

Panama City Division.

The technology is sponsored by the Office of Naval Research

Global TechSolutions program. TechSolutions is ONR Global’s rapid-response

science and technology program that develops prototype technologies to address

issues raised by sailors and Marines, usually within 12 months.

“This rebreather system is an awesome opportunity to enhance

the capabilities of Navy divers and accelerate their deployments,” said Navy

Command Master Chief Petty Officer Matt Matteson, who heads up TechSolutions

for the Office of Naval Research.

Navy diving missions include underwater rescues, explosive

ordnance disposal, ship hull maintenance, recovery of sunken equipment and

salvage of vessels and aircraft.

Beneath the waves, Navy divers breathe a mixture of oxygen

and nitrogen. Below 150 feet, however, nitrogen becomes toxic -- leading to

nitrogen narcosis, a drowsy state that can dull mental sharpness severely and

jeopardize safe return to the surface.

Conserving Helium

The solution is to replace nitrogen with helium. However,

helium is expensive and hard to obtain because of recent worldwide shortages.

And the Navy needs a lot of it for missions and training exercises, requiring

canisters of the gas to be transported on accompanying ships or planes.

The MK29 rebreather solves these problems. Used

oxygen-helium is filtered through a carbon dioxide scrubber, which removes

carbon dioxide and recycles the breathable gasses back to the diver.

The result? Very little venting or wasted helium.

“The MK29 decreases helium requirements by approximately 80 percent,”

said John Camperman, a senior scientist overseeing the development of the MK29

at NSWC Panama City. “Divers can perform more dives with the same amount of

gas, or bring less helium.”

Test results suggest this system will be a major asset to

Navy divers, who can not only perform more dives but also stay underwater

longer if surface supply gas is interrupted.

Titanium Tubing Adds Safety Factor

The MK29 even reduces breathing noise and fogging of helmet

viewports. It’s also the first piece of Navy diving equipment to feature

3D-printed titanium tubing that connects hoses from the helmet’s breathing

manifold to the regulator backpack. The titanium reduces the risk of breathing

hoses being sliced by sharp or jagged underwater objects.

The idea for the MK29 came from a Naval Surface Warfare

Center Panama City Division master diver, who contacted TechSolutions seeking a

way to reduce helium consumption while using newly available rebreather

technology. Recognizing the expertise of Camperman and his team, TechSolutions

asked them to develop the MK29.

Camperman’s research team will conduct further MK29 tests

this year, and hope to see the rebreather issued throughout the fleet by next

year.

No comments:

Post a Comment