Space Force guardians are participating in the 45th iteration of Cobra Gold for the first time in the exercise's history, marking a milestone for the service and further integrating space as a warfighting domain within one of the Indo-Pacific's largest multinational exercises, Feb. 23 to March 6.

The presence of guardians at Cobra Gold signals the continued evolution of the Space Force. It reinforces the U.S.-Thai alliance by enhancing multinational crisis response, mission effectiveness and capability across all domains.

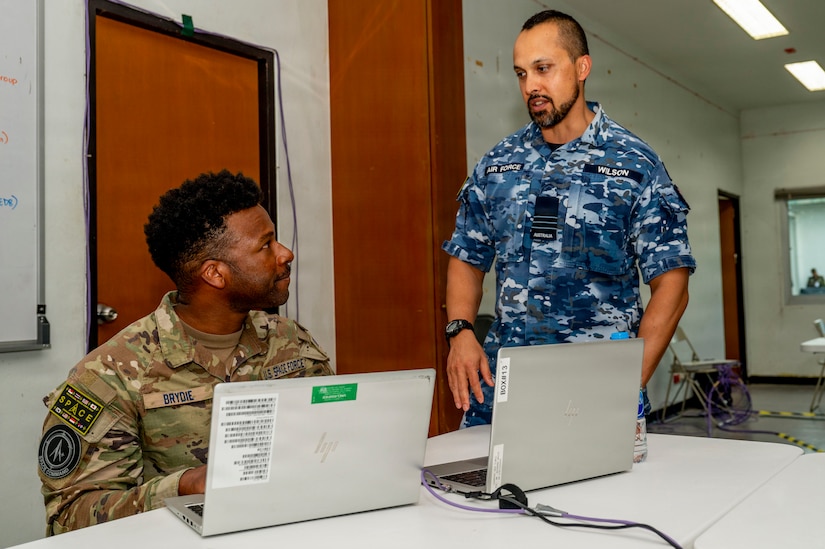

"This marks a significant milestone for the United States Space Force," said Space Force Maj. Jonathan Brydie, a military exchange program embed assigned to the Joint Force Space Component, Headquarters Joint Operations Command. "As our service continues to mature, our participation demonstrates that we can support real-world operations and major multinational exercises simultaneously. It reinforces that space is a warfighting domain. Integrating space from the outset ensures the joint force operates with synchronized effects across air, land, maritime, cyber and space."

As the Air Force's newest military service, the Space Force was established to organize, train and equip forces to protect the United States and allied interests in, from and to space. Its integration into Cobra Gold reflects both operational necessity and the evolving character of warfare.

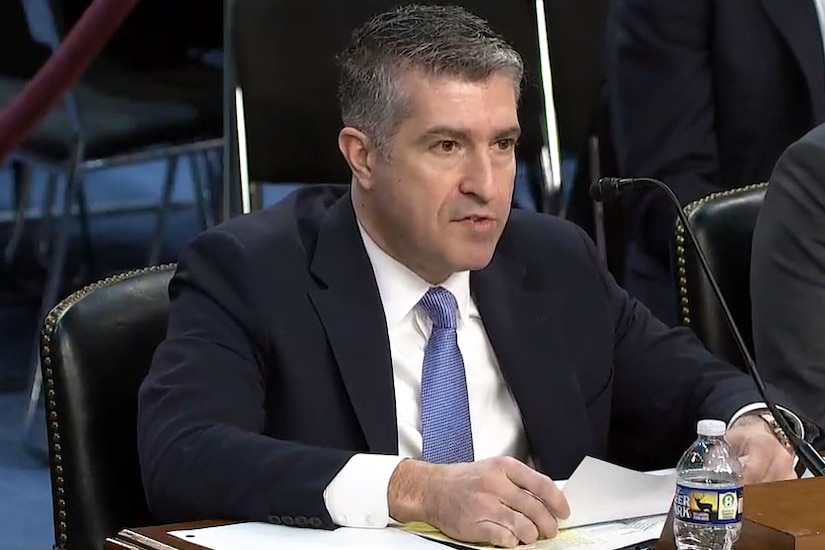

"Integrating space into Cobra Gold enhances the exercise by educating Indo-Pacific partners on the operational role of the space domain during conflict," said Space Force Capt. Nicholas Braga, Space Forces Korea chief of future operations. "It also opens dialogue on how nations can responsibly develop and integrate space capabilities that contribute to regional stability."

In support of Cobra Gold, guardians contributed expertise in space domain awareness, defensive and offensive space operations and operational-level space planning required to maintain space superiority. Rather than operating in isolation, Space Force personnel are embedded alongside air, land, maritime and cyber planners to integrate space effects into decision-making processes.

"We are ensuring space is a deliberate consideration at every decision point," Braga said. "Branch plans and contingency options are developed with space effects integrated from the beginning, giving commanders greater clarity and flexibility in achieving mission objectives."

The operational importance of space domain awareness was a central theme throughout the exercise.

"Most command and control systems rely on satellites and space-enabled networks," Brydie said. "Space superiority is now as vital as air superiority in modern conflict. Maintaining awareness of the space environment allows us to protect those systems and ensure the joint force can operate without disruption."

Beyond operational integration, Cobra Gold provided an opportunity for the Space Force to deepen relationships with regional allies actively developing their own space competencies.

"It has been a tremendous opportunity to collaborate with partner nations," Braga said. "The United States is not the only space-capable entity in this region. Working alongside the Republic of Korea and other allies strengthens trilateral and multilateral integration. The cohesion built here enhances deterrence and reinforces our collective posture across Indo-Pacom."

Coalition partners emphasize shared responsibility in the space domain is essential to regional stability.

"Participating in Cobra Gold demonstrates a shared commitment to the responsible and secure use of space," said Royal Australian Air Force Staff Officer Mark Wilson, wing commander of Joint Force Space Component, Headquarters Joint Operations Command. "It shows we are willing and capable of sharing information and operational experience to achieve common security objectives."

"For the U.S. Space Force, Cobra Gold 2026 serves as both a milestone and platform to demonstrate the service's ability to integrate seamlessly within a complex multinational environment while delivering operational advantage to the joint force," Braga said.

From space domain awareness to operational-level planning, guardians ensured space effects were integrated at every stage of execution reinforcing deterrence, strengthening alliances and advancing the service's role as an essential component of joint and coalition operations in the Indo-Pacific.