Virginia's Norfolk Naval Shipyard has a long and storied tradition of utilizing innovative technology to support its mission and keep its workforce safe. The emergence of the COVID-19 pandemic has strengthened the shipyard's ongoing commitment to innovation as it seeks new ways to keep personnel safe while getting ships back to the fleet on time. The newest invention to make its way through the gates of NNSY is NanoSeptic technology.

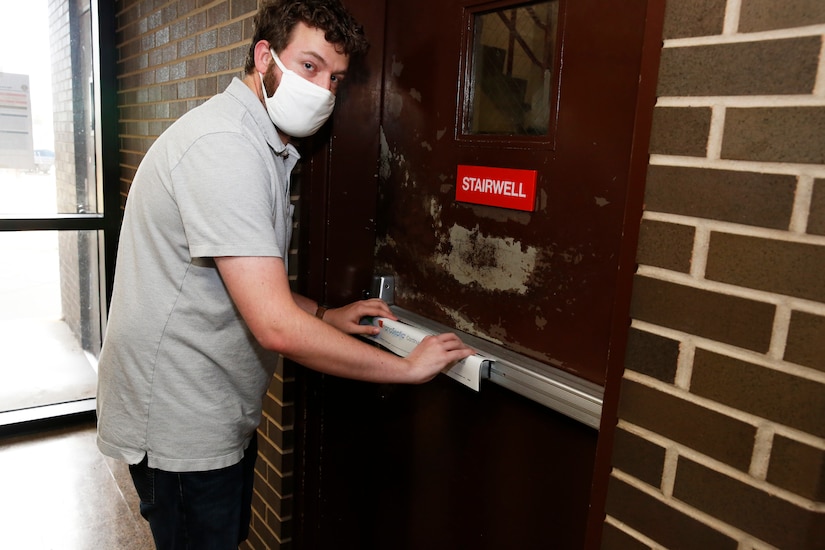

NanoSeptic technology kills pathogens using a photocatalytic reaction with embedded titanium dioxide nanoparticles. In plain language, it can provide a self-disinfecting surface for high traffic areas by using UV light. The technology uses a septic coating on self-adhesive plastic sheets that self-clean every time they're touched.

According to Rob Harrington, code 2310.4 (Ventilation Support) branch head, "NanoSeptic technology can provide a self-disinfecting surface for high traffic areas that will protect NNSY employees from the spread of COVID-19."

Harrington added that the supplier of this technology specified that the NanoSeptic sheets can last for more than three months with minimal cleaning and maintenance.

The technology has been researched by NNSY's Reactor Engineering Division and championed by its Nuclear Engineering and Planning Department Management as NNSY has rigorously and relentlessly pursued ways to keep its employees and their families safe.

"We are well into the process of implementation on a trial basis," Harrington said.

Since NanoSeptic technology is so new, research is still being conducted. To date, the technology has not been approved by the Centers for Disease Control and Prevention or the World Health Organization; however, those involved with the project feel positive about the future of the technology, Harrington said.

"There are virtually no safety concerns, and we have engaged with Code 106 [NNSY's Occupational Safety, Health, and Environment Office] to ensure there are no safety concerns for the shipyard," Harrington added. "Thus far, Code 106 is optimistic."

Though the CDC recently clarified that surfaces are not the primary way that COVID-19 spreads, the NanoSeptic efforts help ensure employee health while highlighting NNSY's diligence and commitment to workplace safety.

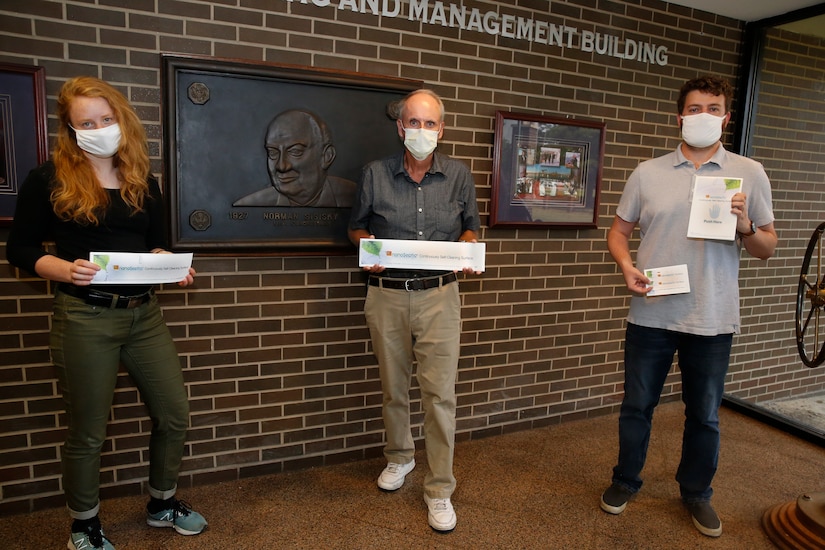

The project has been a team effort between Ventilation Support and NNSY's Supply Department. Key personnel involved in the effort include Mike Kwiatkowski, Cynthia Raines, Ben Campbell and Mark Ragsdale, along with Harrington. It's the third project the department has implemented to promote workplace safety during the COVID-19 pandemic. The others include development of a disinfecting Nuclear Standard Instruction, the use of hydrogen peroxide for disinfecting cognizant nuclear spaces, and the possible use of ultraviolet light technology.

The NanoSeptic project and the efforts that predated it are an example of NNSY's C.O.R.E. values in action, Harrington said.

"It demonstrates that we care about our workforce and that we have a responsibility to do whatever we can to keep NNSY safe," Harrington said.

In a recent message, Navy Vice Adm. Bill Galinis, commander of Naval Sea System Command said, "Our shipyards showed the ingenuity required to get the job done in difficult times. From the shop floor to Code 100, you led the way to protect your coworkers."

The health and safety of the workforce remains the top priority, and NanoSeptic technology is just one innovative example of how shipyard employees are working diligently every day to help minimize the spread while maximizing the mission.

(Allison Conti is assigned to Norfolk Naval Shipyard)

No comments:

Post a Comment